FormFactor - Cascade Custom Probe Systems - Comprehensive technical and application know-how for challenging applications

Customized Solutions for a Variety of Challenging Applications

We are your partner for challenging applications. Our comprehensive technical and application know-how over all probe system platforms and our expertise for customized products is based on an extensive experience over many years. We offer a special demo support in-house or at the customer, as well as after sales support for complicated setups.

Customization Examples

Waveguide with customized bracket

300 mm chuck with large tweezer pocket

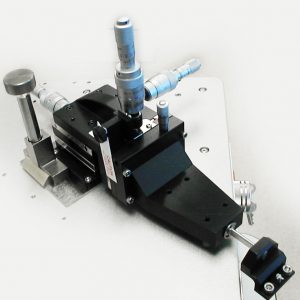

RF positioner with micrometer screws

Double-side setup for emission microscopy

Combined microscope movement for scope and black body

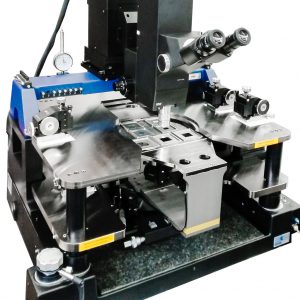

mmW setup with North/South positioner platform

More Product Information

An extensive range of optical, electrical and mechanical accessories for LUMIMAX® LED Lights simplify both adaptation to customer-specific requirements and the connection to the machine environment. The innovative solutions allow for compact, fast and easy integration of LUMIMAX® LED Lights. This saves additional design and mounting work, which means that significant cost savings can be achieved.

- Ultra-low, fA-level current and fF-level capacitance measurements from -65 °C to + 300 °C

- Guarantees fully-guarded measurements to fA and fF levels

- Individual connectors provide force-sense connection for quasi-Kelvin and CV measurements

- Allows probing of different pad materials and sizes

- Fast replacement of worn probes without the need for tools

-

High power – 66 W at 2.4 GHz and 43 W at 5 GHz

-

Extremely low insertion loss of ≤ 0.4 dB (typical) up to 40 GHz

-

Excellent contact control and low contact resistance

-

High performance on any pad material (Al or Au)

-

Longest lifetime – typically one million (1,000,000) touchdowns

- Tackle demanding imaging applications using an eighth-generation Intel Core processor

- Capture directly from GigE Vision® and USB3 Vision® cameras

- Broaden support for Camera Link® , CoaXPress® , DisplayPort, HDMI, and SDI video interfaces using Zebra frame grabbers

- Customize I/O capabilities through four PCIe slots accepting full-height, half-length cards

- Install in space-limited industrial environments given its small footprint and rugged design

- Streamline application development using the Aurora Design Assistant flowchart-based IDE or the Aurora Imaging Library SDK

- Tackle machine vision applications with utmost confidence using field-proven tools for analyzing, locating, classifying, measuring, reading, and verifying

- Leverage machine learning including deep learning to categorize image content

- Ready for deep learning training with suitably equipped and configured model

Flexibility

- Different substrate carriers for wafers up to 100 mm or single dies

- Up to six positioners

- Use with liquid nitrogen or helium, depending on the target temperature

- Probing with an open chamber lid possible under atmospheric condition

- Specially designed for laboratory environments

- Covers wide range of measurements (I-V, C-V, RF, MEMS, OPTO)

See "Specifications & Details" tab for more key features

- High Intensity: up to 9x brighter than the existing SL191 Pattern Projecting Spot Light and more than 3x brighter than the leading competitive structured light projector.

- Projection patterns are easily configured with available reticles, including line, grid, cross, multiple lines, and half sphere, with custom reticles available.

- Customizable: available in multiple wavelengths, including white.

- Constructed with a large heat sink for improved LED thermal management to facilitate increased brightness while maintaining safe operating temperatures.

- Ideal solution for machine vision inspection applications requiring structured illumination, including edge detection, locating offsets, and assessing topography.

- Requires a reticle and lens (sold separately); see available reticles here.

- Probe loss is 3 dB typical between 140 and 200 GHz, S11/S22 15 dB typical

- Reduced unwanted couplings and transmission modes

- Able to shrink pad geometries to 25 x 35 µm (best case)

- Typical contact resistance < 0.05 Ω on Al, < 0.02 Ω on Au

- WR15, WR12, WR10, WR8, WR6, WR4, WR3, and WR2 bands available.

The LSProbe 1.2 Variant E Field Probe is a high-speed, high-accuracy, and high-dynamic range electric-Field probe.

- Its standard frequency range of 10 kHz – 8.2 GHz. 1,000 V/m

- Best-in-class compensation of linearity, frequency, and temperature guarantees accurate measurements from less than 0.1 to at least 1,000 V/m.

- A dynamic range of 100 dB is achieved for many frequencies, enabling Field measurements at more than 10,000 V/m.

- Customized high Field-strength „X“-variants, supporting up to 30,000 V/m and a damage level of 100,000 V/m, are available upon request.

Flexibility

- Ideal for a wide range of applications such as RF, mm-Wave and sub-THz characterization, FA, DWC, MEMS, optoelectronic tests and WL

- Re-configurable and upgradable as requirements grow

- Minimizes setup times with no loss in performance or accuracy

- Seamless integration of various measurement instruments

Stability

- Solid station frame

- Built-in vibration-isolation solution for superior vibration attenuation

- Rigid microscope bridge

- Compact and rigid mechanical design

- Highly accurate measurement results

- Incorporates best-known methods

Ease of Use

- Ergonomic and straightforward design for comfortable and easy operation

- Low-profile design

- Simple microscope operation

- Quick and ergonomic change of DUT through pull-out stage

- Minimize training efforts

- Fast time to data

- Convenient operation

FormFactor, Inc.

FormFactor, Inc. (NASDAQ:FORM) is a leading provider of essential test and measurement technologies along the full IC life cycle – from characterization, modeling, reliability, and design de-bug, to qualification and production test.

We constantly strive to help our customers solve the advanced test and measurement challenges of the broader semiconductor industry. Our focus on customer partnership, innovation, agility and operational excellence allows us to earn sustainable business every day.