LUMIMAX - LED Area Lights & Flat Domes

LUMIMAX® LED area lights are for versatile use in all areas of Machine Vision for incident or backlight tasks. Their designs allow for any arrangement around the object to be inspected.

LED Area lights in the LG series are based on our LightGuide technology. State-of-the-art LightGuide technology guarantees the maximum degree of homogeneity and irradiance intensity over the entire light field. Variants with additional collimation accessories improve image contrast and minimise the glare effect at manual workstations. See in our Video - Principle Collimated Backlight Video the detailed principle of the collimated backlight.

The area lights of the LGCB series with a camera hole can also be used as a flat dome within a reflected light application and thus create a full-area, shadow-free illumination of the test object.

With the lightings of the BASIC series even price-sensititve applications can be reliably implemented.The focus here is on the realization of essential functions at high quality. A smart and lightweight design ease the integration in confined or moving machine vision systems.

Go to the product configurator for your desired lighting

|

Homogeneous Area Lights with LightGuide Technology |

|

|

|

From 100 x 100 mm to 400 x 300 mm |

|

Homogeneity through lateral light injection |

|

Highly diffuse (DL) oder collimated (KOL) lighting |

|

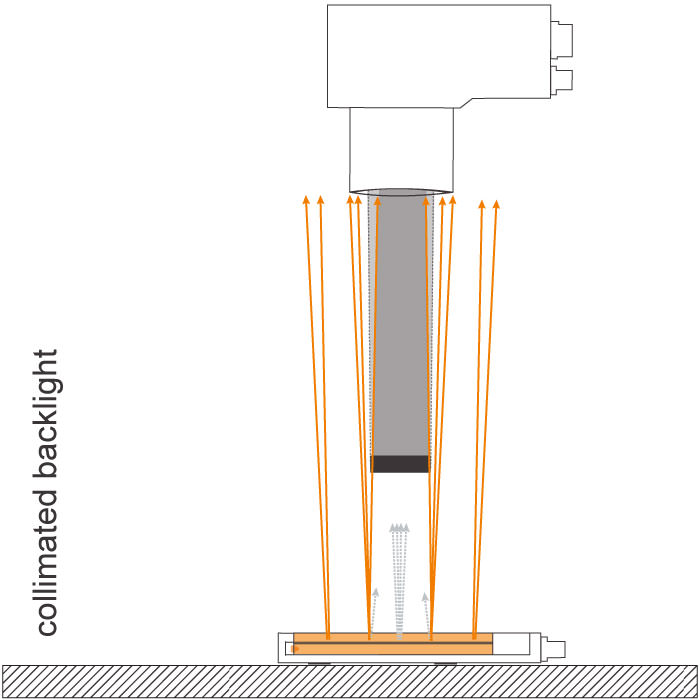

Principle - Collimated Backlight

|

|

Collimated backlight |

|

A directed, homogeneous area light source is positioned behind the object |

|

The contours of the object are lit for a secure control of the object's outline as well as (open) inside contours |

|

The light rays from the lighting are significantly directed (almost telecentric) an d achieve a precise image of object edges without disturbing overlays/reflections |

|

Area of application: dimensional accuracy checks, contour inspection, machined hole and thread inspection, inspection of transparent or semitransparent objects (foils, glass) |

|

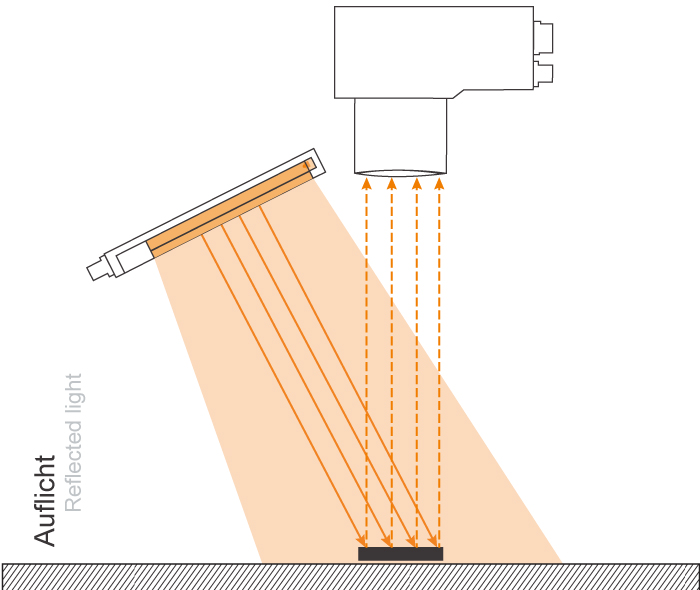

Principle - Collimated Reflected light

|

|

Reflected light (partial bright field) |

|

Area lighting is used to direct light onto the test object at a slight angle |

|

Collimated lighting aims to provide wide, homogeneous and intense light over the entire image field, also from a larger distance |

|

Area of application: for mirrorlike, semitransparent and transparent test objects, such as foil, labels and glass |

|

Flat Dome Lights with LightGuide Technology |

|

|

|

From 200 x 200 to 400 x 300 mm |

|

Homogeneity through lateral light injection |

|

Mounting on the camera side |

|

Highly diffuse (DL) or collimated (KOL) lighting |

|

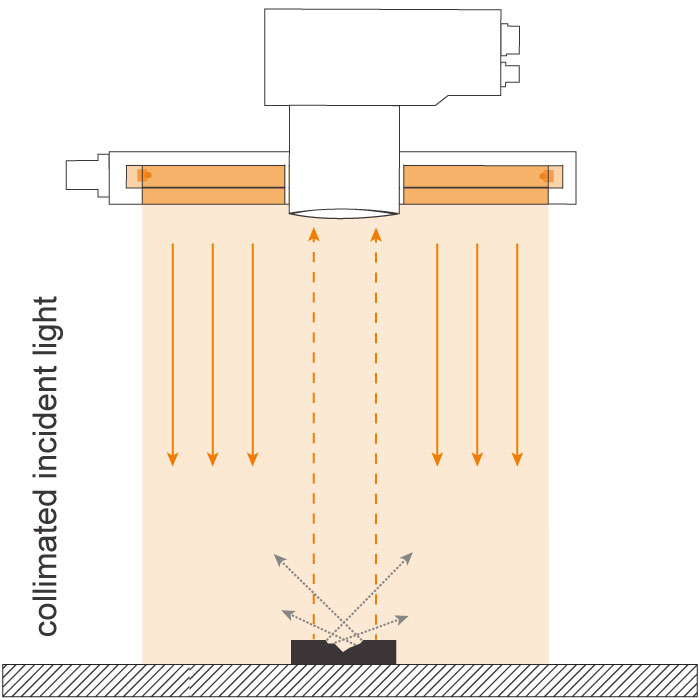

Principle - Collimated area Lights with a camera hole

|

|

Reflected light (bright field) |

|

A directed, camera-mounted area light is used to produce the light beam onto the test object and is fully reflected. The object appears bright. |

|

Surface structures, e.g. scratches, blow holes, engravings, reflect the light beam and appear dark in the camera image |

|

Area of application: assembly, type and position detection, surface inspection of reflective and mirrorlike materials |

|

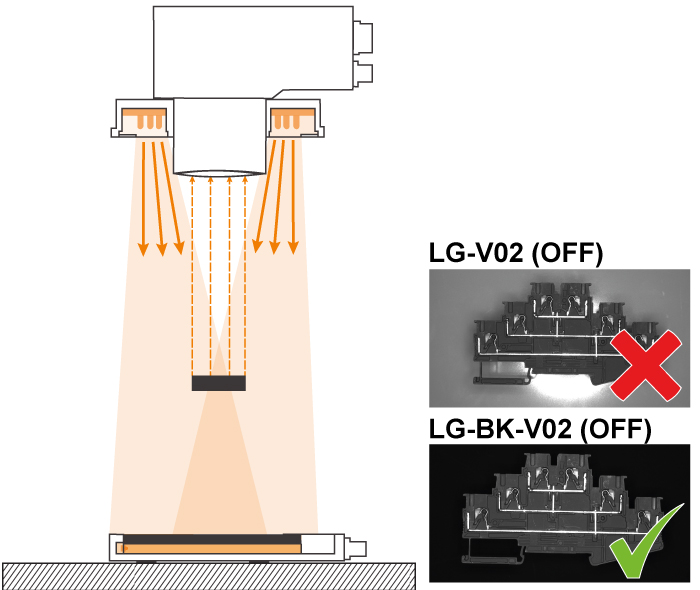

BLACK series for combined applications |

|

|

|

From 100 x 100 mm to 400 x 300 mm |

|

Highly diffuse backlight through LightGuide Technology |

|

Black light area (BK) when switched off as low-reflecting background for reflected-light applications |

|

Principle - LG-V02 BLACK series

|

|

Combination of reflected light and backlight |

|

Reflected light: A camera-mounted ring light is used to produce the light beam onto the object to check the presence of the test features |

|

Backlight: The contour of the object is checked with diffuse area Lighting (LG-BK-V02) |

|

Special feature: Black illuminated surface (LG-BK-V02) eliminates reflections of the ring lighting |

|

Flexible High Performance Lights |

|

|

|

From 40 x 40 mm to 80 x 80 mm |

|

Light output up to 5 million lux |

|

Flexible adjustments through versatile accessories |

|

Highly diffuse (DL) or collimated (KOL) lighting |

|

Principle - Collimated backlight LQHP

|

|

Collimated backlight |

|

A directed, homogeneous area light source is positioned behind the object |

|

The contours of the object are lit for a secure control of the object's outline as well as (open) inside contours |

|

The light rays from the lighting are significantly directed (almost telecentric) and achieve a precise image of object edges without disturbing overlays/reflections |

|

Are of application: dimensional accuracy checks, contour inspection, machined hole and thread inspection, inspection of transparent or semitransparent objects (foils, glass) |

|

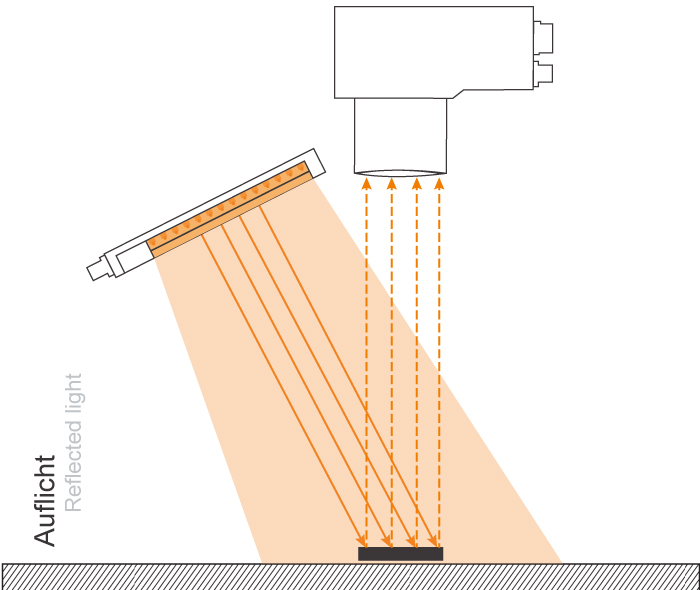

Principle - collimated reflected light LQHP

|

|

Reflected light (partial bright field) |

|

Collimated lighting aims to provide wide, homogeneous and intense light over the entire image field, also from a larger distance |

|

Area of application: for mirrorlike, semitransparent and transparent test objects, such as foil, labels and glass |

|

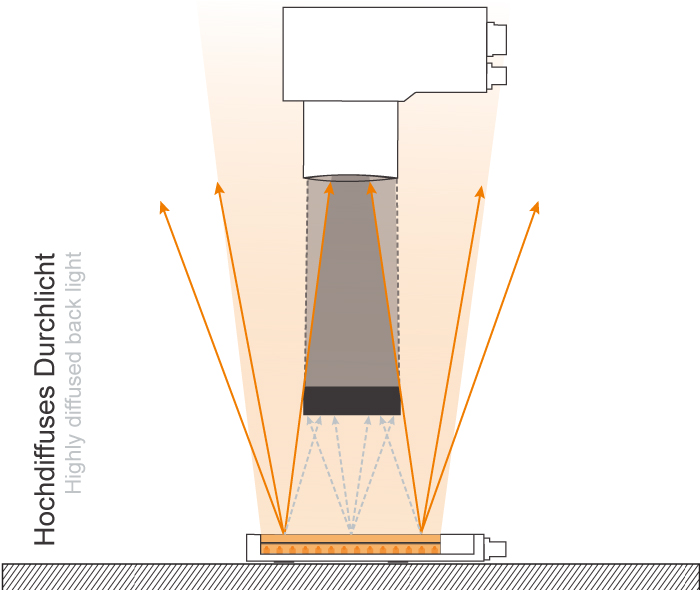

Principle - diffuse backlight LQHP

|

|

Highly-diffuse backlight |

|

A diffuse area light is positioned behind the object |

|

The contours of the test object are lit in order to inspect outlines as well as free inner contours |

|

Area of application: level control, damage inspection in transparent or semitransparent object surfaces, type and position detection. |

|

Area Lights for Extreme Performance |

|

|

|

From 40 x 40 mm to 80 x 80 mm |

|

Cooling element for double brightness increase |

|

Flexible adjustment through versatile accessories |

|

Highly diffuse (DL) or collimated (KOL) lighting |

|

Principle - collimated backlight LQXP

|

|

Collimated backlight |

|

A directed, homogeneous area light source is positioned behind the object |

|

The Contours of the object are lit for a secure control of the object's outline as well as (open) inside contours |

|

The light rays from the lighting are significantly directed (almost telecentric) and achieve a precise image of object edges without disturbing overlays/reflections |

|

Area of application: dimensional accuracy checks, contour inspection, machined hole and thread inspection, inspection of transparent or semitransparent objects (foils, glass) |

|

Principle - collimated reflected light LQXP

|

|

Reflected light (partial bright field) |

|

Area lighting is used to direct light onto the test object at a slight angle |

|

Collimated lighting aims to provide wide, homogenous and intense light over the entire image field, also from a larger distance |

|

Area of application: for mirrorlike, semitransparent and transparent test objects, such as foil labels and glass |

|

Principle - diffuse backlight LQXP

|

|

Highly-diffuse backlight |

|

A diffuse area light is positioned behind the object |

|

The contours of the test object are lit in order to inspect outlines as well as free inner contours |

|

Area of application: level control, damage inspection in transparent or semitransparent object surfaces, type and position detection |

|

Compact BASIC Area Lights |

|

|

|

From 25 x 25 mm to 200 x 200 mm |

|

For price-sensitive applications |

|

Lightweight housing design |

|

Directed (30°) or highly diffuse (DL) lighting |

|

Principle – BASIC Area Lights – backlight

|

|

Backlight |

|

A diffuse area light source is positioned behind the object |

|

The contours of the object are lit instead of the object itself |

|

The contours of the test subject are lit in order to inspect outlines as well as free inner contours |

|

Area of Application: presence inspection, damage inspection in transparent or semitransparent object surfaces, type and position control |

|

Principle – BASIC Area Lights – reflected lighting

|

|

Reflected light (partial bright field) |

|

Area lighting is used to direct light onto the test object at a slight angle |

|

Area of application: Assembly, type and position detection, printed material inspection, surface finish inspection, OCR / OCV |

More Product Information

LUMIMAX

LUMIMAX® is a brand of iiM GmbH by Exaktera.

The LUMIMAX® brand stands for developing and manufacturing high-performance and highly functional LED lights for Machine Vision applications in a very wide range of industrial areas, such as for the automobile, semiconductor, pharma, food, drinks and tobacco industries.

Contact Details

iiM GmbH Neuer - LUMIMAX

Friedberg 5, 98627 Suhl, Germany

Phone: +49 3681 / 455 19-0

Email: info@iimag.de