AVT - Mako G-234 2.35 Megapixel machine vision camera with Sony IMX CMOS sensor

-

Monochrome (G-234B) and color (G-234C) models

-

GigE Vision interface with Power over Ethernet

-

Screw mount RJ45 Ethernet connector for secure operation in industrial environments

-

IEEE 1588 Precision Time Protocol allows for easy synchronization of multiple cameras and devices on network

-

Trigger over Ethernet Action Commands allow for a single cable solution to reduce system costs

-

Supports cable lengths up to 100 meters (CAT-6 recommended)

-

Comprehensive I/O functionality for simplified system integration

-

Popular C-Mount lens mount

-

Easy camera mounting via standard M3 threads on top and bottom of housing or optional tripod adapter

-

Easy software integration with Allied Vision's Vimba Suite and compatibility to the most popular third party image-processing libraries.

-

Select between B 270 ASG protection glass and filter types: Jenofilt 217 IR cut filter, Hoya C-5000 IR cut filter, RG715 IR pass filter, or RG830 IR pass filter

Mako G-234 is a 2.35 megapixel GigE machine vision camera that incorporates the high quality Type 1/1.2 (13.4 mm diagonal) Sony IMX249 CMOS sensor. At full resolution, this camera runs 41.5 frames per second (10-bit sensor readout). With a smaller region of interest, higher frame rates are possible.The Mako G-234 is an ideal replacement for legacy CCD models.

Mako G cameras have the same ultra-compact form factor and the same mounting positions as many analog cameras. All models include Power over Ethernet, three opto-isolated outputs, and a 64 MB image buffer. The image quality profits from the precisely aligned sensor. By default monochrome models ship with no optical filter and color models ship with a Type Hoya C-5000 IR cut filter.

See the Modular Concept for lens mount and optical filter options.

See the Customization and OEM Solutions webpage for additional options.

Specifications

Imaging performance

Imaging performance data is based on the evaluation methods in the EMVA 1288 Release 3.1 standard for characterization of image sensors and cameras. Measurements are typical values for monochrome models measured at full resolution without optical filter. Contact Sales or AE for more information.

Output

Operating conditions/dimensions

Features

Image optimization features:

- Auto gain (manual gain control: 0 to 40 dB; 0.1 dB increments)

- Auto exposure (exposure time control varies by pixel format)

- Auto white balance (G-234C only)

- Binning

- Color correction, hue, saturation (G-234C only)

- Decimation

- Gamma correction

- One look-up table

- Region of interest, separate region for auto features

- Reverse X/Y

Camera control features:

- 10-bit or 12-bit sensor readout mode

- Event channel

- Image chunk data

- IEEE 1588 Precision Time Protocol

- Storable user sets

- StreamBytesPerSecond (bandwidth control)

- Stream hold

- Sync out modes: Trigger ready, input, exposing, readout, imaging, strobe, GPO

- Temperature monitoring (main board only)

- Trigger over Ethernet Action Commands

Applications

Mako G-234 is ideal for a wide range of applications including:

- Robotics

- Quality control

- Inspection, surveillance

- Industrial imaging

- Machine vision

- Logistics

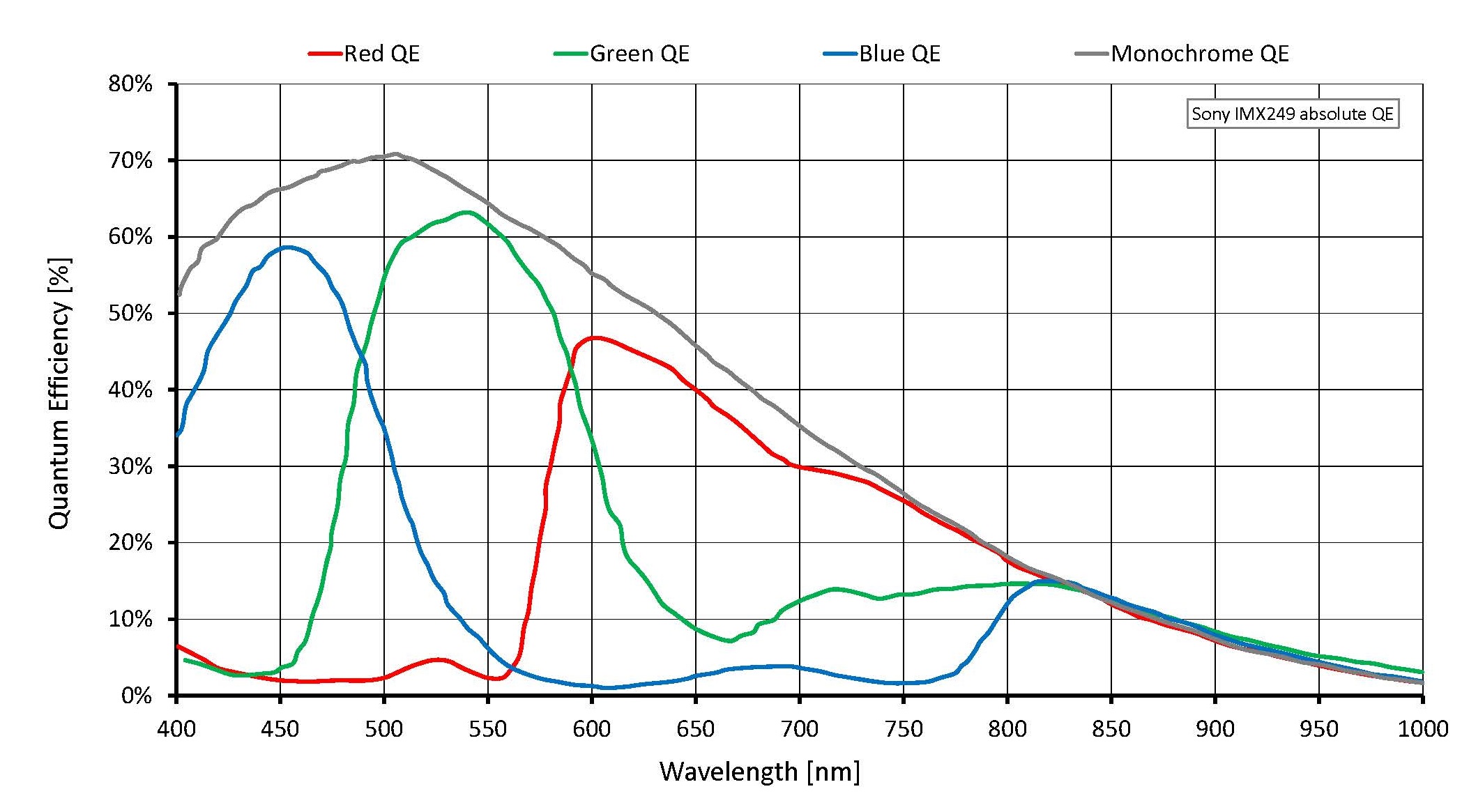

Quantum efficiency

Technical papers, knowledge base

3D CAD files (STEP)

Please right-click the link of a 3D camera model and select save as to download the file. After downloading, unzip the STEP file. You need a 3D CAD viewer application to view and measure the STEP files. Download a STEP viewer free of charge: https://www.freecadweb.org/

Software and firmware

Vimba is our current future-proof SDK.

Other SDKs and tools are available on our Software downloads webpage.

GigE camera firmware is available on our Firmware webpage.

More Product Information

Allied Vision Technologies

Firewire, Gigabit Ethernet and Camera Link Cameras